In the plastic injection molding process, several critical factors must be considered. Plastic materials, injection machine, and the level of expertise all interplay and influence the final production outcome. Utilizing CAE molding analysis software for verification and optimization will be indispensable in the future of the plastic molding industry, allowing companies to proactively identify and eliminate potential defects, thus accelerating the production process.

CoreTech System, known for its commitment to delivering high-quality and high-performance molding analysis software – Moldex3D, has officially released an innovative molding cloud platform in 2023 – “Moldiverse.†Moldiverse offers various online services, including a plastic material database, machine characterization data analysis and digital resources for plastic processing. These services enable users to access the latest resources and support in the plastic industry. With a highly flexible and convenient platform environment, Moldiverse assists companies in significantly reducing operational cost and enhancing product competitiveness, making it a crucial digital transformation solution for business.

Fig 1 Moldiverse – Innovative molding cloud platform

Â

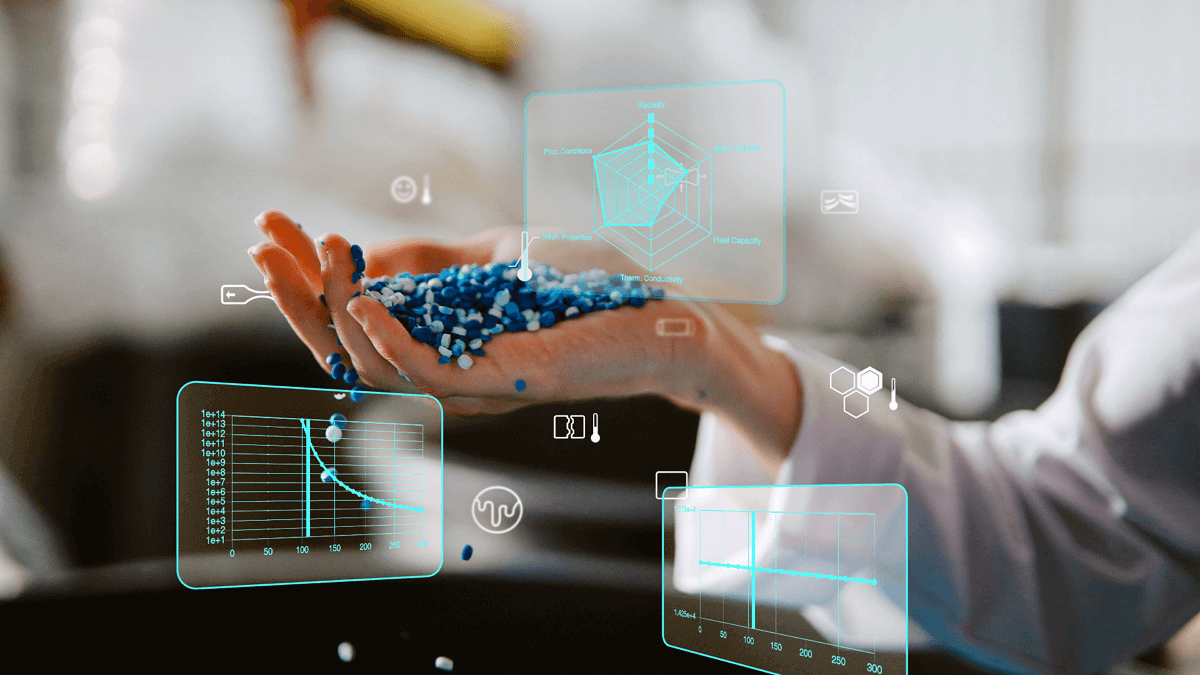

MHC (Material Hub Cloud) –A powerful material database will lead an outstanding product.

Material properties are one of the most critical factors that influence the quality of molding and finished products. Through the user-friendly interface of MHC (Material Hub Cloud) you can quickly assess various practical features for plastic materials at just a click. These features include evaluating material properties and molding conditions, recommending approximate materials based on industry and product characteristics, rapidly cross comparing the characteristics of multiple materials, and assisting in establishing accurate material files. This essential material information can be applied in CAE molding simulations to ensure more precise analysis results.

Fig 2 Â Assessing necessary material information through MHC

Â

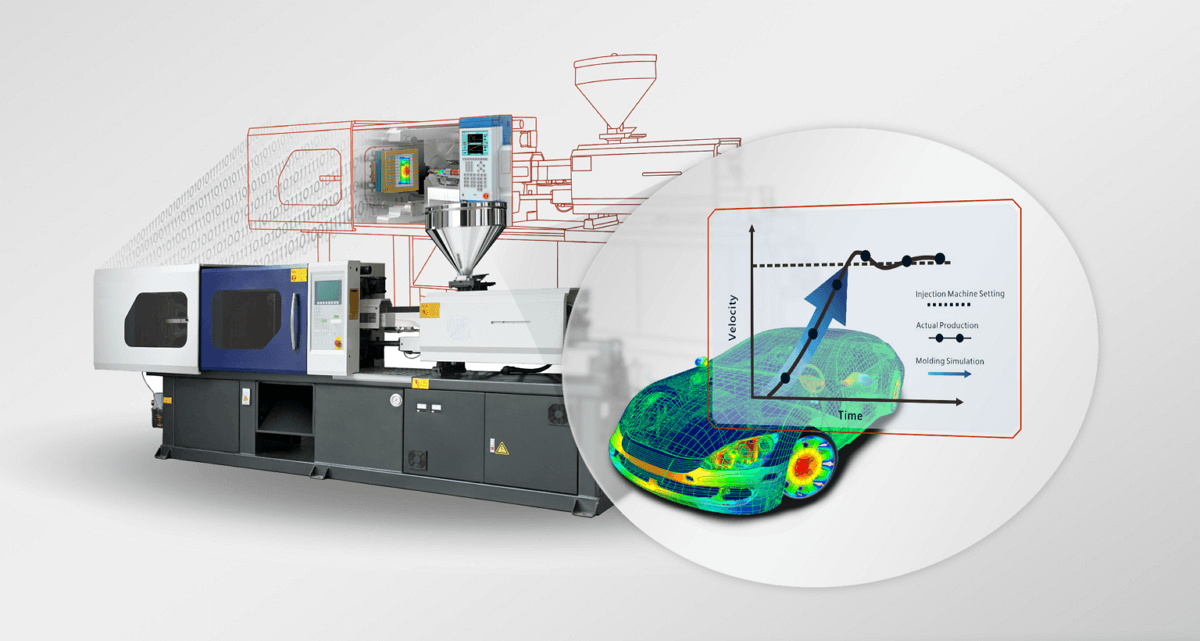

iMolding Hubï¼Link simulation and production, creating a unique digital twin for each machine

Establishing a comprehensive injection database is an important milestone for companies moving to Industry 4.0. iMolding Hub enables users to instantly upload real-time machine feedback, coupled with cutting-edge machine characteristic services, to create a unique identity for each machine. All of this can be easily managed using just mobile phone and tablet, allowing users to monitor the status of all machines effortlessly, thereby enhancing efficiency and saving time. Users can download machine characteristic reports and analysis reports after submitting machine data on iMolding Hub. This allows the unique capabilities and dynamic responses of individual machines to be applied in CAE molding analysis, resulting optimized conditions that closely align with the actual production environment.

Fig 3 Â Achieve digital twin and intelligent manufacturing through machine characteristics

Â

Universityï¼The outstanding learning platform of the plastic process industry

In the world of plastic molding, new knowledge continually emerges. To keep pace with the times and even stay one step ahead, an efficient learning and training system is crucial. To meet the pursuit of knowledge for everyone, we released “Moldex3D University,†an online learning platform that explores deep into the realm of plastic industry knowledge. Bringing together years of industry expertise and Moldex3D specialists, Moldex3D University is tailored to provide a professional platform for plastic molding knowledge. Its content includes selected webinars, interactive plastic injection molding tutorials, and Moldex3D CAE operation courses. With Moldex3D University, you can easily grasp professional knowledge, gain insights from industry experts, enhance your competitiveness anytime and anywhere, and embrace a wealth of learning opportunities. With Moldex3D University, your learning never stops.

Fig 4Â Acquire professional plastic processing molding knowledge through Moldex3D University

Â

Through Moldiverse, teams can not only overcome innovation obstacles but also find solutions to the challenges encountered in different stages of the design process. With just one account, users can access all Moldiverse’s cloud services, gaining material database and learning resources, enabling smart design and smart manufacturing.

Experience Moldiverse right now! Explore the vast universe in digital simulation and plastic industry together.

Suzhou Gold ant Precision Sheet Metal Co.,Ltd , https://www.jmyplatemetals.com